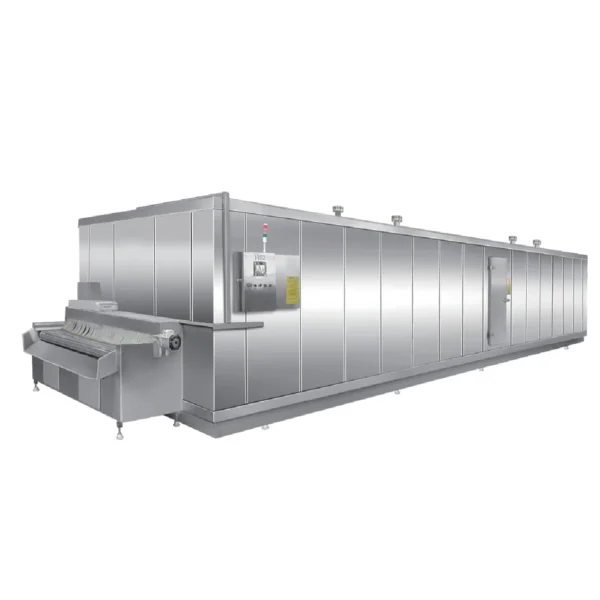

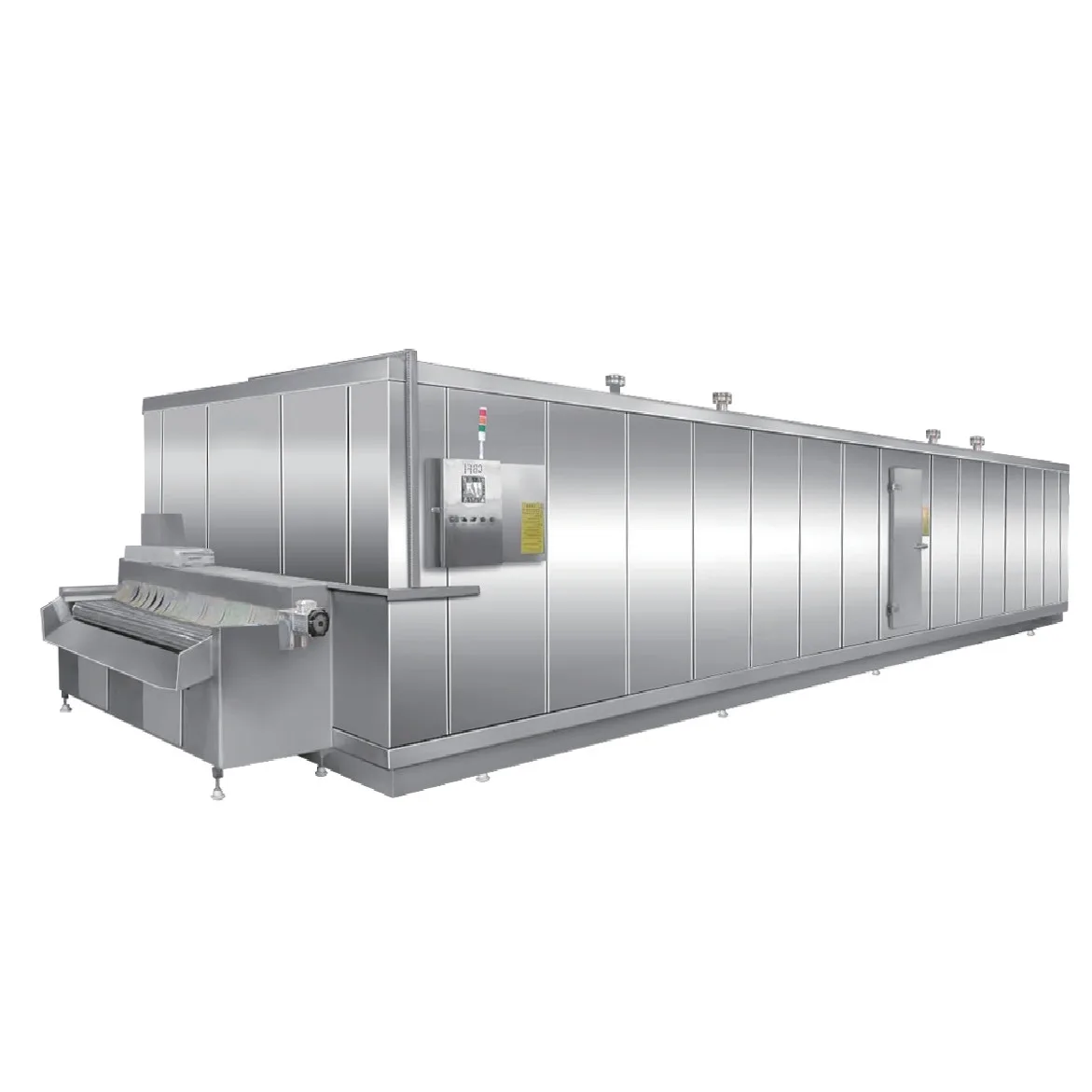

Equipment characteristics

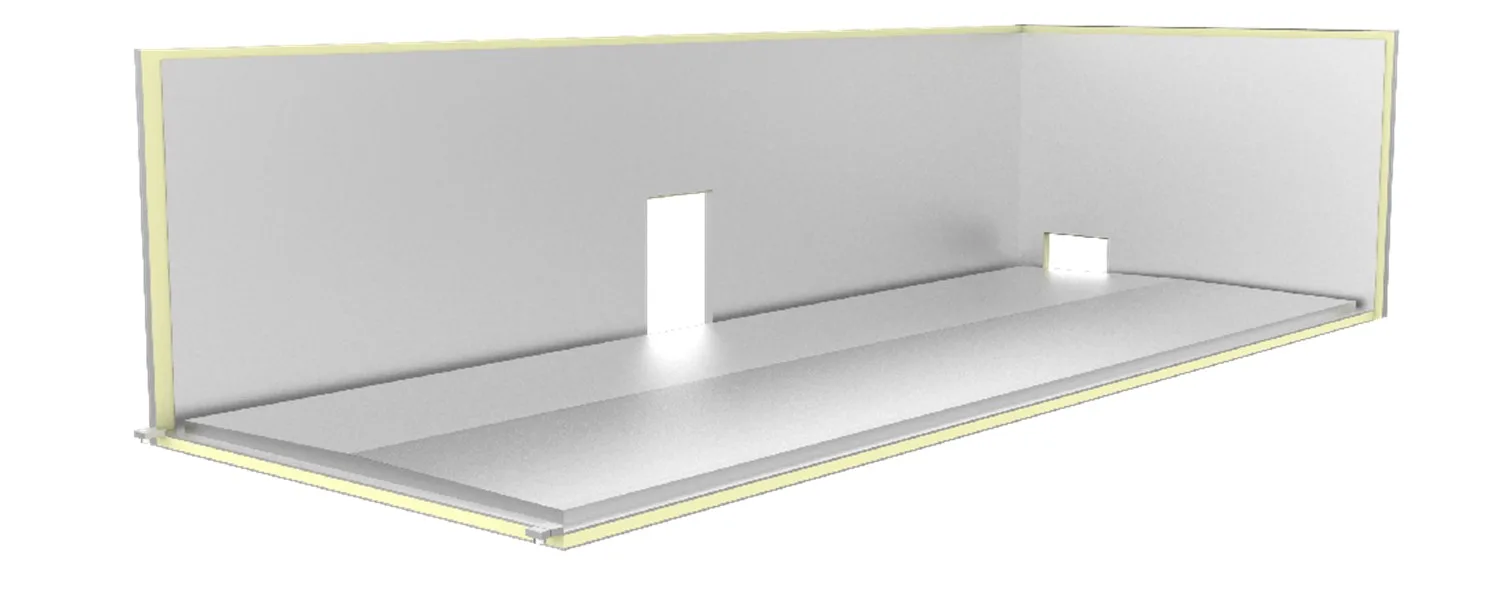

Thermal insulation system

The insulated warehouse body is made of stainless steel polyurethane sandwich panel. The wall thickness of the panel is 0.6mm. The internal polyurethane is foamed by high-pressure charging with an imported high-pressure foaming machine. The polyurethane material is American HUNTSMAN product. The filling volume is ≥42kg/ m3, the thickness of the storage board is S=120mm, and there are concave and convex joints between the panel.

There is a self-limiting temperature heating device between the warehouse door and the door frame, with a safety voltage level of AC36V, to keep the warehouse door open at any time; the warehouse door is equipped with an induction door magnetic switch to ensure safe production; there is a push-type opening handle on the inside of the warehouse door. Prevent personnel from being closed in the library under abnormal circumstances.

The entire bottom surface of the storage tank is made of stainless steel plates to form an integrated sink. There are drainage ditches on both sides. The middle protrusion in the storage tank forms a gap with the drainage ditch. The drainage is smooth and does not accumulate water, making it easier to clean.

There are two drainage outlets at the two corners in the direction of the material inlet and outlet, which increases the discharge speed of frost water in the warehouse, shortens downtime, and improves production efficiency; the drainage device is equipped with a stainless steel opening/closing device to reduce cold leaking.

Transmission system

The brackets and rails are made of entirely stainless materials, and the parts in contact with the conveyor chain plate are made of ultra-high molecular polyethylene friction-reducing material.

Transmission mesh belt: The mesh belt is made with imported special equipment, with smooth surface and long service life. The mesh belt is made of food-grade SUS304 material. The core rod is Φ8mm, the mesh wire is Φ1.5mm, and the pitch of the mesh wire is 6mm.

The transmission adopts advanced variable frequency power supply control, and the speed can be infinitely adjusted. With the unique mesh belt tensioning technology, it can ensure the stability and reliability of the overall transmission.

heat exchange system

The evaporation tube of the evaporator is made of aluminum alloy, and the fins are made of rust-proof aluminum alloy. The liquid supply and heat exchange methods are advanced and efficient. The evaporation tube is φ20mm×2mm, the fin thickness is 0.4mm, the fins are large, and the fin pitch structure is variable. , the tubes are densely arranged, have good heat exchange, and are easy to clean. Stainless steel outer frame, the evaporator undergoes a pressure test of 24kg/cm3 before leaving the factory, and the pressure is maintained with dry nitrogen for 24 hours.

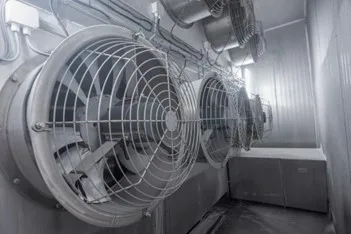

The ventilation system uses an axial flow fan, a fully enclosed low-temperature, moisture-proof and waterproof motor, which is highly efficient, energy-saving, low-noise, and operates smoothly. The air duct and protective cover are made of stainless steel; the air return and return are smooth and the freezing effect is good.

The evaporator liquid supply and return pipe interface is outside the library to connect with the external liquid supply and return pipe.

refrigeration unit

Unique two-stage compressor unit design, low operating temperature or high compression ratio to meet low temperature and high efficiency requirements. Operating temperatures up to -60°C. This unit uses a two-stage compressor unit. The system includes a lubrication system and a control system. Each container of this system is equipped with an electronic pressure sensor and a safety valve. When the system pressure is abnormal, an alarm will be issued and the system protection program will be automatically executed.

The compressor will automatically adjust energy from 25% to 100% according to the cooling load. This compressor unit stands out among compressor units at -42°C/+38°C. The efficiency is 30% higher than that of a single-stage compressor unit with an economizer.

The unit frame design simplifies the system structure: the compressor, economizer (supercooler), and oil cooler are assembled on the same unit frame, occupying a small area and saving installation space.

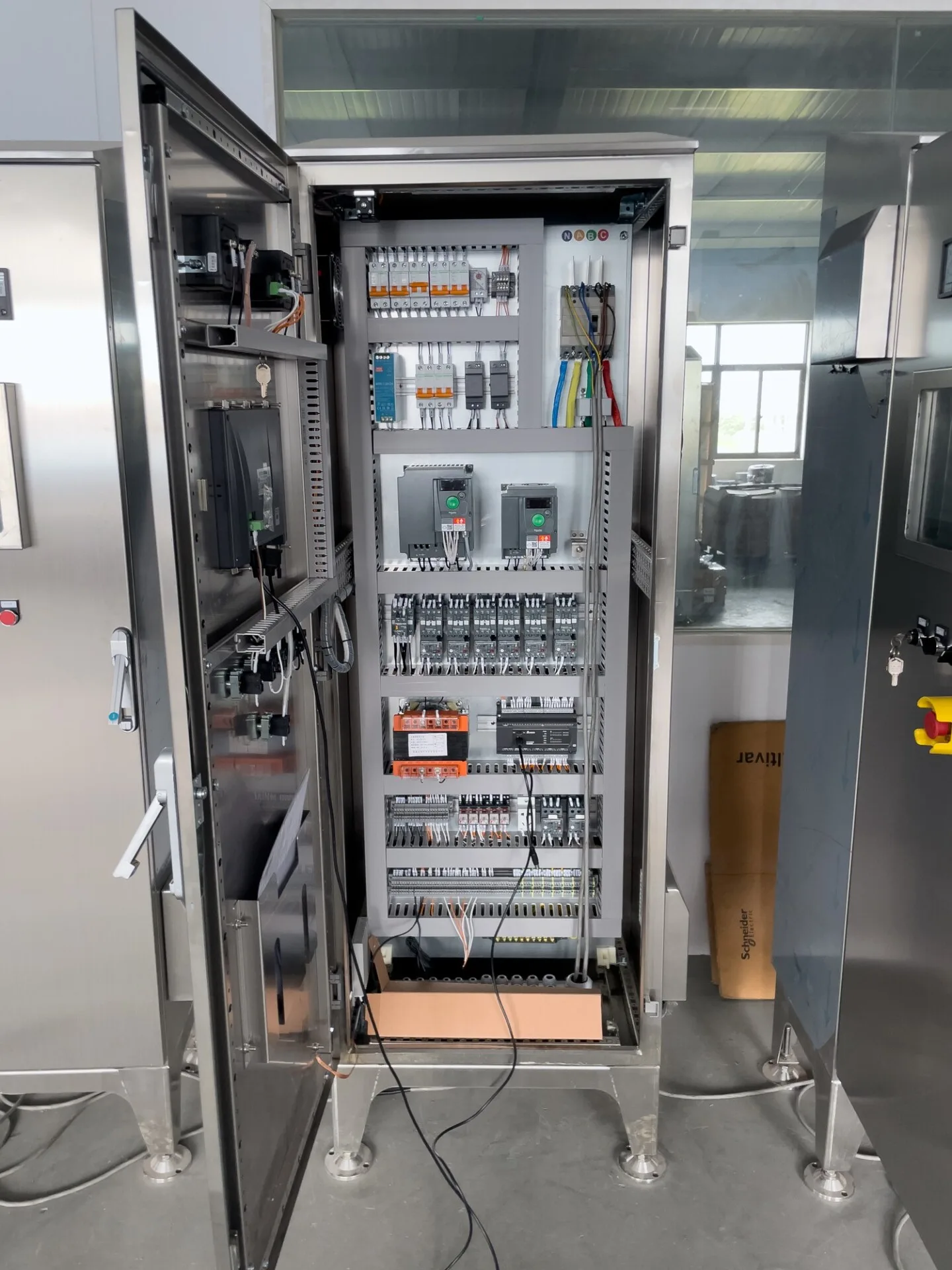

Electronic Control System