superfine powder packing machine

Superfine powder packing machine is used to fill superfine powder 200mesh above and light density, which will cause powder spreading during filling and packing process, superfine powder packing machine will fill powder from bag bottom to avoid powder from spreading and guarantee packing accuracy, widely used to automatic quantitative pack and continuous automatic quantitative measurement of milk powder, monosodium glutamate, white sugar, glucose, solid medical powder, powdered additives, dyes, Lithium chloride powder and similar powdered materials.

Technical features

Superfine powder packing machine is integrated controlled by program, electricity and compressed air, with features as below

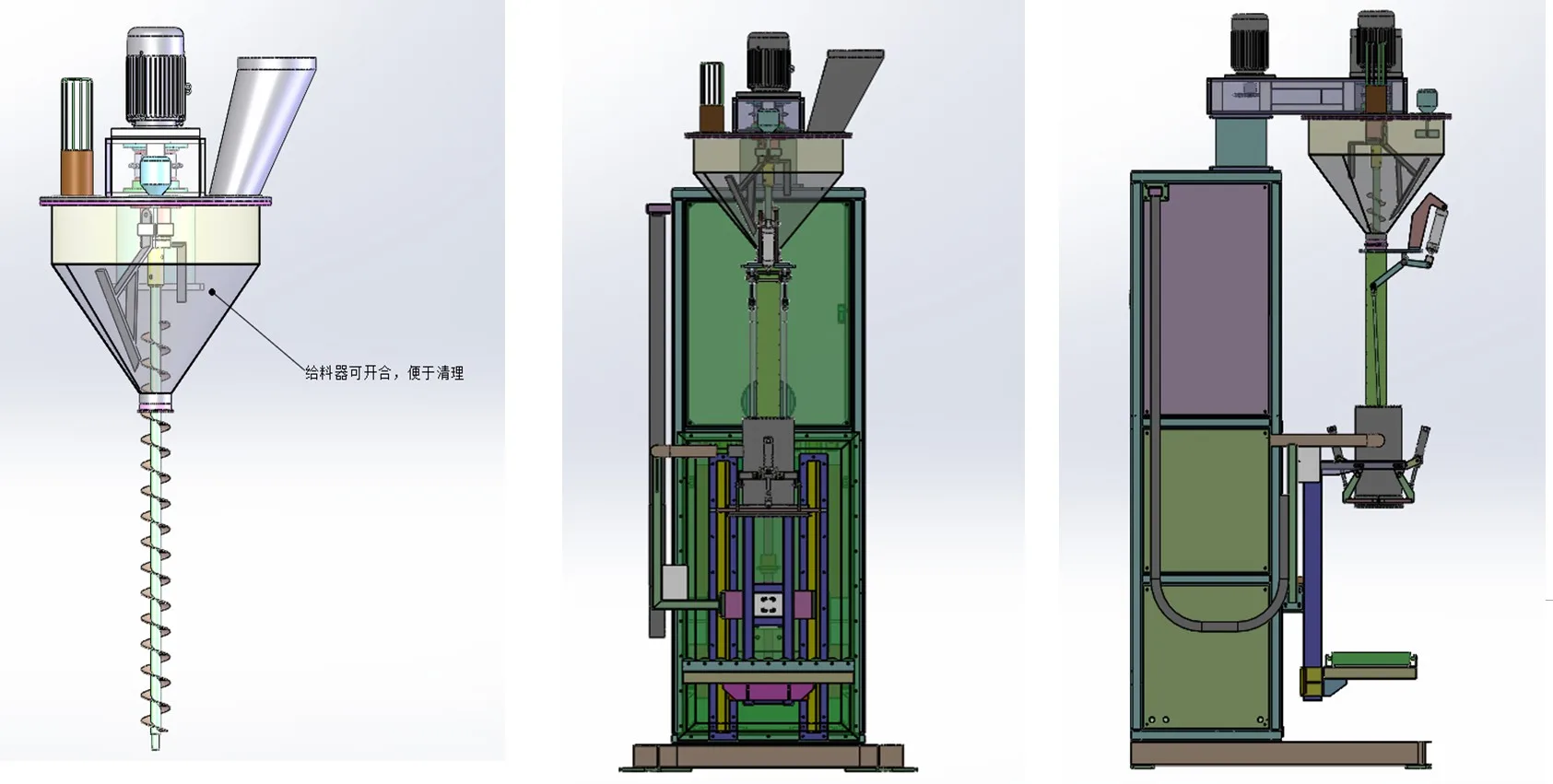

- 1Vertical auger filling, stable and accurate. The cone-bottom stop valve ensures the controlling ability of the material during the filling process.

- 2Open-able silo and quick-release auger assembly, which makes the cleaning on machine hopper simple and fast, without dead corners.

- 3Filling head fill materials from bottom to top, prevent powder from spreading and guarantee accuracy.

- 4English and other language for HMI touch screen, simple and fast operation, good stability, and clear working status.

- 5High-precision sensor, discharge with stop gate design to improve packaging accuracy;

- 6All stainless steel 304 material, polished inside and outside surfaces.

Technical parameter

Component | Item | Parameter |

|---|---|---|

Weighing sensor | Stroke range | 10-50kg |

Quantity | 1set | |

Sensitivity | 0.5μv/d, 20±0.2mv/v | |

Working temperature | -20-50℃ | |

Brand | Mettler-Toledo, 1set | |

Material | Alloy steel | |

Filling device | Filling method | Vertical auger |

Filling motor | 1.5kw, 1piece, speed adjustable | |

Buffer hopper | 0.3m³ SUS304, 2mm thick | |

Lever motor | 0.75Kw, 1piece | |

Control | High and low resistance rotary material level control | |

Diameter | 200mm | |

Mounting form | Soft cloth connection | |

Auger | SUS304,800-1000mm long | |

Cutoff valve | Pneumatic, silicon gasket sealing | |

Weighing system (lifting structure) | Bag clamping hopper | SUS304 |

Clamp | AirTac clamp cylinder x 2piece | |

Conveyor | PVC belt conveyor, speedless roll | |

Frame and guardrail | SUS304 | |

Lifting motor | 3Kw, 1piece | |

Lifting system control | Delta frequency converting | |

Dust collector | Dust collection mode | Cloth bag pulse dust collection |

Reserved inlet | 63mm | |

Pipe | SUS304 | |

Control system | Cabinet material | SUS304 |

Controller | Siemens PLC control | |

Control system | English and other language option for HMI | |

Protection grade | IP grade | IP54/IP55 |