Customized Design

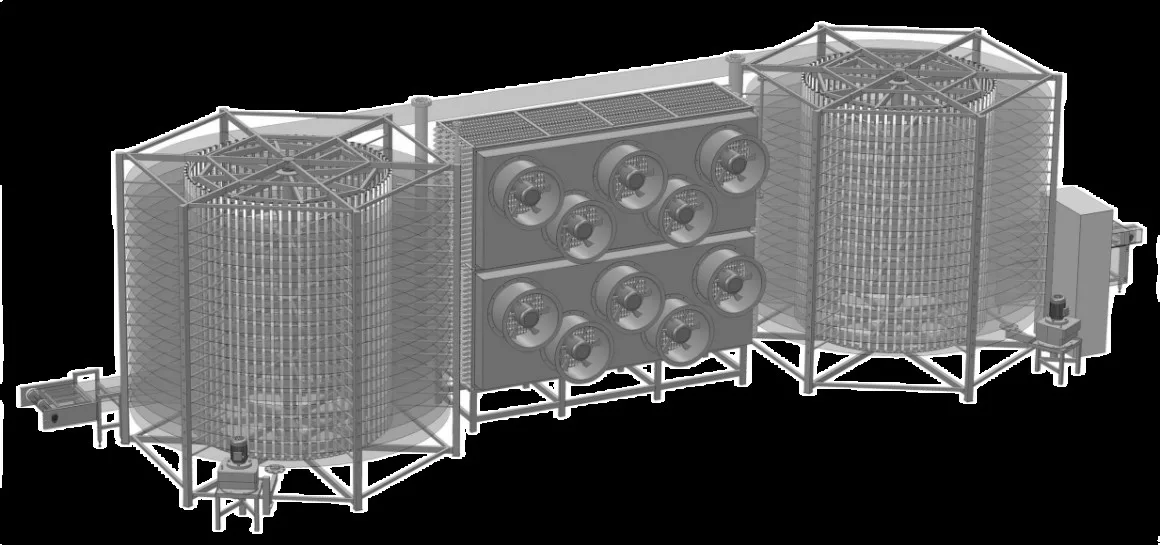

Continuously maintain high-efficiency freezing ability. The product feed temperature is very high, and when the chicken nuggets enter the quick-freezer body, a large amount of water vapor will be emitted, which will cause frost on the surface of the evaporator fins and block them, resulting in a decrease in heat exchange capacity. We adopt the B-type structure design, so that the frosting phenomenon of the evaporator occurs at the feed end, thus ensuring that the evaporator at the discharge end can still be in a high-efficiency heat exchange state. It ensures that you can meet the production capacity requirements for a long time, and reduces the consumption of electric energy, saving you the cost of electricity.

Save site space and ensure continuous operation of the factory. Considering the limited length of your site, this plan adopts a double-spiral quick-freezer with 90-degree discharge, which saves space and at the same time allows the feed end and discharge end of the quick-freezer to seamlessly connect with the upstream and downstream equipment, ensuring Improve the continuous operation of your production line and improve production efficiency

Machine Features

Insulation System

Transmission System

The drum, support, and support rails are all made of stainless materials, and the parts in contact with the conveyor belt are made of high-molecular polyethylene anti-friction materials. The stainless steel tumbler spindle adopts a three-stage structure, which is very convenient for inspection and maintenance of the upper and lower bearings.

The main transmission adopts advanced transmission control technology. The large stainless steel sprocket on the drum is almost equal to the diameter of the drum, which reduces the pulling force of the transmission chain, and the rotation of the tumbler is stable and reliable; the low-tension synchronous transmission technology is adopted, and an auxiliary transmission device is set up. Work, can ensure the stability and reliability of the overall transmission

High-strength spiral special horseshoe conveyor belt, the mesh belt strength reaches the strength standard of the world-class mesh belt American "Ashworth", the surface is smooth and beautiful, and the service life is long. Frozen products can be frozen directly on the conveyor belt. The mesh belt is internally contracted, and there are ribs on the chain pieces on both sides, so that the product is not easy to slip off. When the plate is frozen, the plate is not easy to slip out of the mesh belt and collide with other structures to cause chucking. The mesh belt is made of food-grade SUS304 stainless steel, which can ensure product hygiene requirements (this part is only applicable to the spiral freezer)

Heat Exchange System

The tube of the evaporator is made of aluminum alloy, and the fins are made of anti-rust aluminum alloy. The liquid supply and heat exchange methods are advanced and efficient. The evaporation tube is φ20mm×2mm, the fin thickness is 0.4mm, the fins are large, and the pitch structure is variable. , The tubes are densely arranged, the heat exchange is good, and the cleaning is convenient. The outer frame is made of stainless steel, and the evaporator is subjected to a pressure test of 24kg/cm3 at the factory, and the dry nitrogen gas is kept under pressure for 24 hours.

The ventilation system adopts an axial flow fan, a fully enclosed low-temperature moisture-proof and waterproof motor, which is efficient, energy-saving, low noise, and runs smoothly. The motor blades are made of rustproof aluminum alloy, and the air duct and protective cover are made of stainless steel; The return air flow is smooth and the freezing effect is good.

The evaporator supply and return pipe interface is located outside the warehouse for connection with external supply and return pipes.

Refrigeration System

Unique two-stage compressor unit design, low operating temperature or high compression ratio to meet low temperature and high efficiency requirements. Operating temperatures up to -60°C. This unit uses a parallel unit of two two-stage compressors. The system includes a lubrication system and a control system. Each container of this system is equipped with an electronic pressure sensor and a safety valve. When the system pressure is abnormal, an alarm will be issued and the system will be automatically executed protector.

The compressor will automatically adjust energy from 25% to 100% according to the cooling load. This compressor unit stands out among compressor units at -47°C/+38°C. The efficiency is 30% higher than that of a single-stage compressor unit with an economizer.

The unit frame design simplifies the system structure: the compressor, economizer (supercooler), and oil cooler are assembled on the same unit frame, occupying a small area and saving installation space.

IOT Internet of Things cloud system: Internet of Things technology + cold chain technology application to solve the stability requirements during equipment operation and determine the operating performance of the equipment.

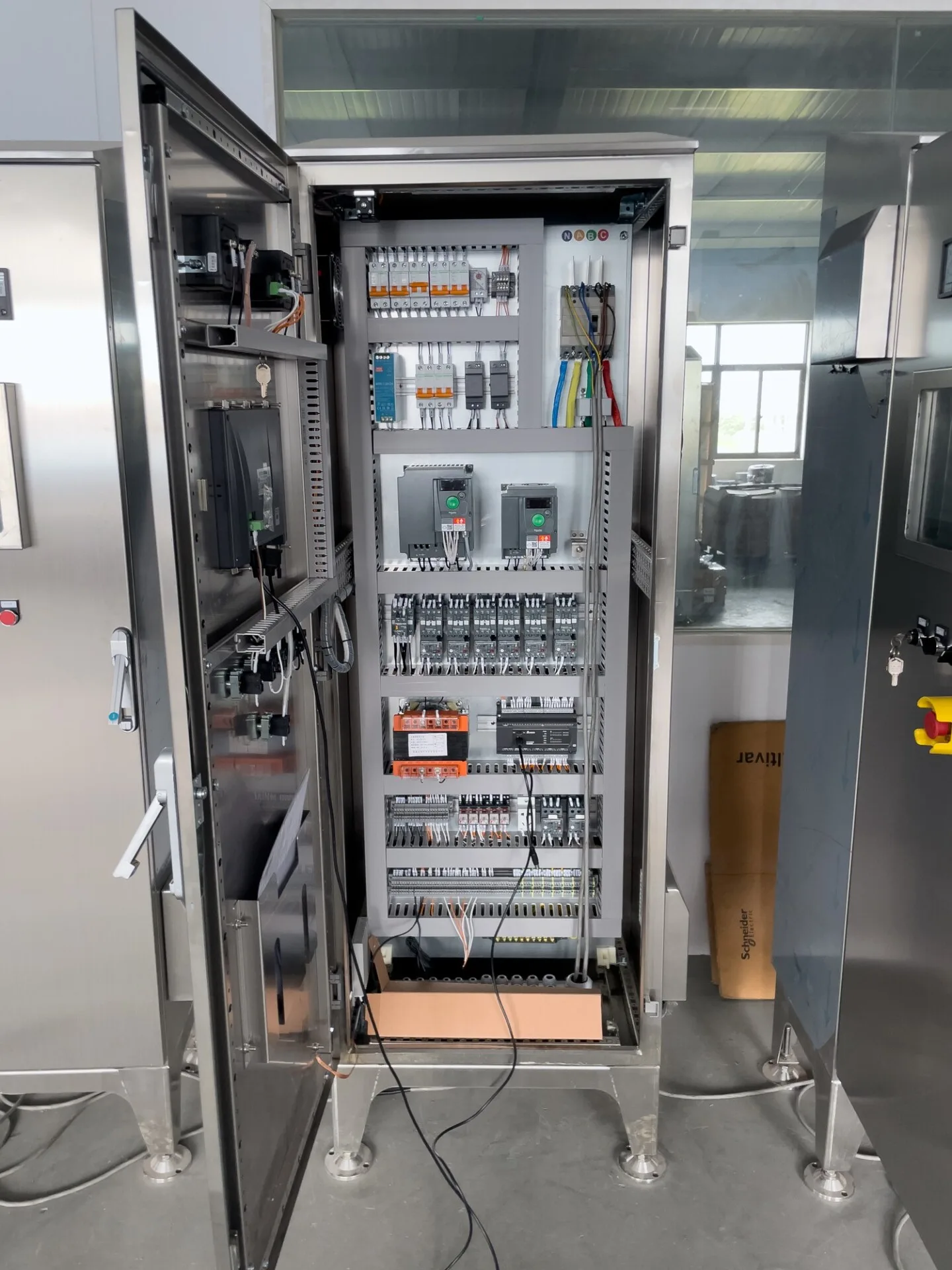

Electronic Control System

The main electrical control components are produced by Schneider Electric Company in France, and the temperature in the warehouse is displayed digitally.

The operation of the mesh belt adopts variable frequency power supply control, and the mesh belt speed achieves stepless adjustable speed change.

The safety detection device for the operation of the mesh belt adopts an imported contactless proximity switch, with reliable performance.

Electrical centralized control cabinet: It adopts all stainless steel control cabinet (European standard cabinet) with a protection level of IP55