Application

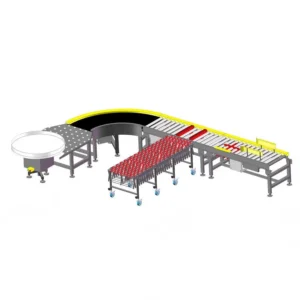

Full automatic premade pouch bagger, featured with rapid reaction, reliability and quick changeover, is ideal for a large variety of bag types and range. Equipped with Z-shape bucket elevator and combination scale, it is widely applied to candies, microwave popcorn, cookies, nuts, rice, coffee beans, crops, peanuts, etc.

Technical characteristics:

Processes:

JT-series pre-made pouch bagger can be clarified into 8 working stations and 6 working stations in terms of station amounts in one machine. Specifically, the whole processes are involved in the following stations:

1. | Pouch-picking Station (Required) |

2. | Date-printing Station (Required) |

3. | Pouch-opening Station (Required) |

4. | Material-filling Station-1 (Required) |

5. | Material-filling Station-2 (Optional) |

6. | Air-exhausting Station (Optional) |

7. | Matrial-detecting Station (Optional) |

8. | Sealing and Outputting Station (Required) |