Open Packing Machine(powder, granule)

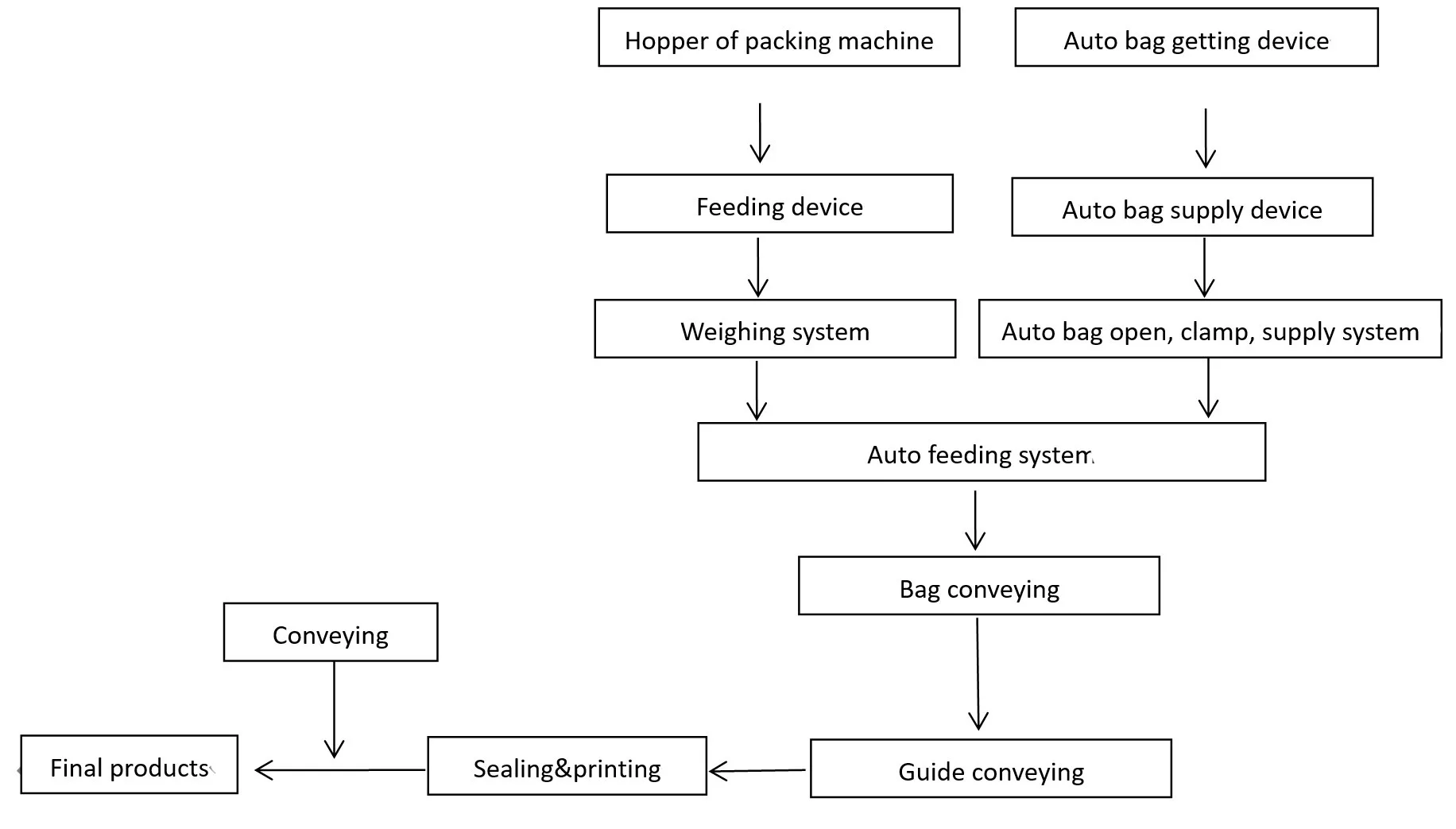

生产流程

包装机:用于管道和索赔重装

K50/S 门式双包装机

模型 | 称重 | 毕业价值 | 准确性 | 速度 | 电压 | 空气消耗量 |

|---|---|---|---|---|---|---|

K50/S | 5-50公斤 | 1-10克 | ≤0.2% | 500-600袋/小时 | 380V/50HZ/3P | 1立方米/小时 0.3-0.5兆帕 |

1. 应用

广泛用于饲料、谷物、肥料、大米、种子、化工产品、食品、塑料颗粒、生物质颗粒的定量包装。

2.最新任选功能

1)光电感应自动修剪和缝纫;

2)自动集袋导向功能;

3)管道机的自动升降调节;

4)全链板式管道机;

3.特点

1) 用途

配备高精度传感器和高智能称重控制器,稳定准确。具有自动校正空白托盘、自动跟踪零点、过冲检测与增益、超量和欠量报警等功能。

易于维护和维修

模拟状态下的强制执行功能真正实现了故障自诊断,维护和修复。

生产连续稳定,使用寿命长

在手动状态下的强制执行功能中,作为一项事故措施,当自动控制过程失效时,可以在不解除包装作业的情况下手动完成整个包装过程。AirTac气动执行器性能优异,其进出口压力可调,使工作更加可靠且无污染。与托盘接触的部件均采用进口不锈钢材质,符合食品卫生要求,耐腐蚀,延长了设备的使用寿命。

自动统计包裹数量

它具有RS232串口和打印机接口,可以与计算机通信并实现打印数据。

高安全性

气动元件、电器设备和仪器均受到保护,以确保设备和人身安全。

人性化设计

当包装重量发生变化时,传送带高度可自动调节,缝纫机可自动剪线;传送带一个后退开关,可返回进行第二个新娘,以处理有新娘缺陷的包装。

技术参数

物品 | 参数 |

|---|---|

产品 | 颗粒 |

模型 | K50/S |

称重范围 | 净重:10-50公斤/袋,可调节 |

称重速度 | 250-600袋/小时 |

喂养类型 | 分级门式进料 |

袋子尺寸 | 宽度350-650毫米,长度630-1100毫米 |

袋子材料 | 编织袋、牛皮纸袋、复合薄膜塑料袋 |

密封类型 | 编织袋:折叠/缝纫; |

宽容 | ±0.2% |

称重类型 | 悬臂梁 |

称重传感器 | HBM/梅特勒托利多 |

传感器容差 | 0.5μV/d |

传感器工作温度 | -20-50℃ |

传感器材料 | 合金钢 |

温度控制表 | 加拿大通用汽车 |

温度计温度 | -10-40℃ |

仪表A/D转换比 | 每秒 120 次 |

料斗物料 | SUS304 |

包装机械材料 | 与SUS304材料接触的部件 |

过渡料斗 | SUS304材质,厚度2.5mm,容积0.6m³,带密封盖 |

平台、水罐、护栏 | 碳钢材质,表面喷漆,厚度2毫米,100x100毫米支撑架 |

气动元件 | 台湾航空 |

电子元件 | 施耐德 |

进料口 | 与布料的柔软连接 |

内部控制 | 进料斗上准备了除尘器入口。 给料机上准备的除尘装置入口 |