The Freeze drying process effectively removes moisture while preserving the original structure and composition of the product.

Key components of a freeze dryer include:

- 1Freezing Chamber: Where the product is initially frozen.

- 2Drying Chamber: Where the sublimation process occurs under vacuum conditions.

- 3Vacuum System: To create the low-pressure environment necessary for sublimation.

- 4Condenser: To collect the water vapor during the drying process.

- 5Control System: To monitor and regulate the freeze-drying cycle.

Applications of freeze dryers are vast and include pharmaceuticals, food preservation, biological samples, and even in the production of certain consumer goods. The primary benefit of freeze drying is that it allows for long-term preservation without the need for refrigeration, and it can restore the product to its original state by adding water, making it an essential process in various industries.

Industrial small freeze dryer

Model | FD-0.2 | FD-1 | FD-2 |

|---|---|---|---|

Dimension(mm) | 1000*850*1700 | 1700*1000*1900 | 2400*1000*2100 |

Drying area(㎡) | 0.2 | 1 | 2 |

Loading capacity | 2kg | 10kg | 20kg |

Water catch capacity | 5kg | 15kg | 30kg |

Function | Freezing and Drying in one Chamber or Freezing and Drying separated | ||

Chamber material | SUS304 or SUS316L | ||

Shelf material | SUS304 or Aluminium alloy | ||

Freezing Temperature | -35℃ ~ -60℃ or customize | ||

Condenser Temperature | -45℃ ~ -70℃ or customize | ||

Vacuum degree | ≥1pa or customize | ||

Control system | PLC one key automatic control, remote monitoring operation | ||

Heating method | Silicone oil is heated by electricity | ||

Power | 5kw | 10kw | 13kw |

Other functions | automatic cleaning function, sterilization function, block valve function, gland function etc | ||

Any area could be customized according to requirements | |||

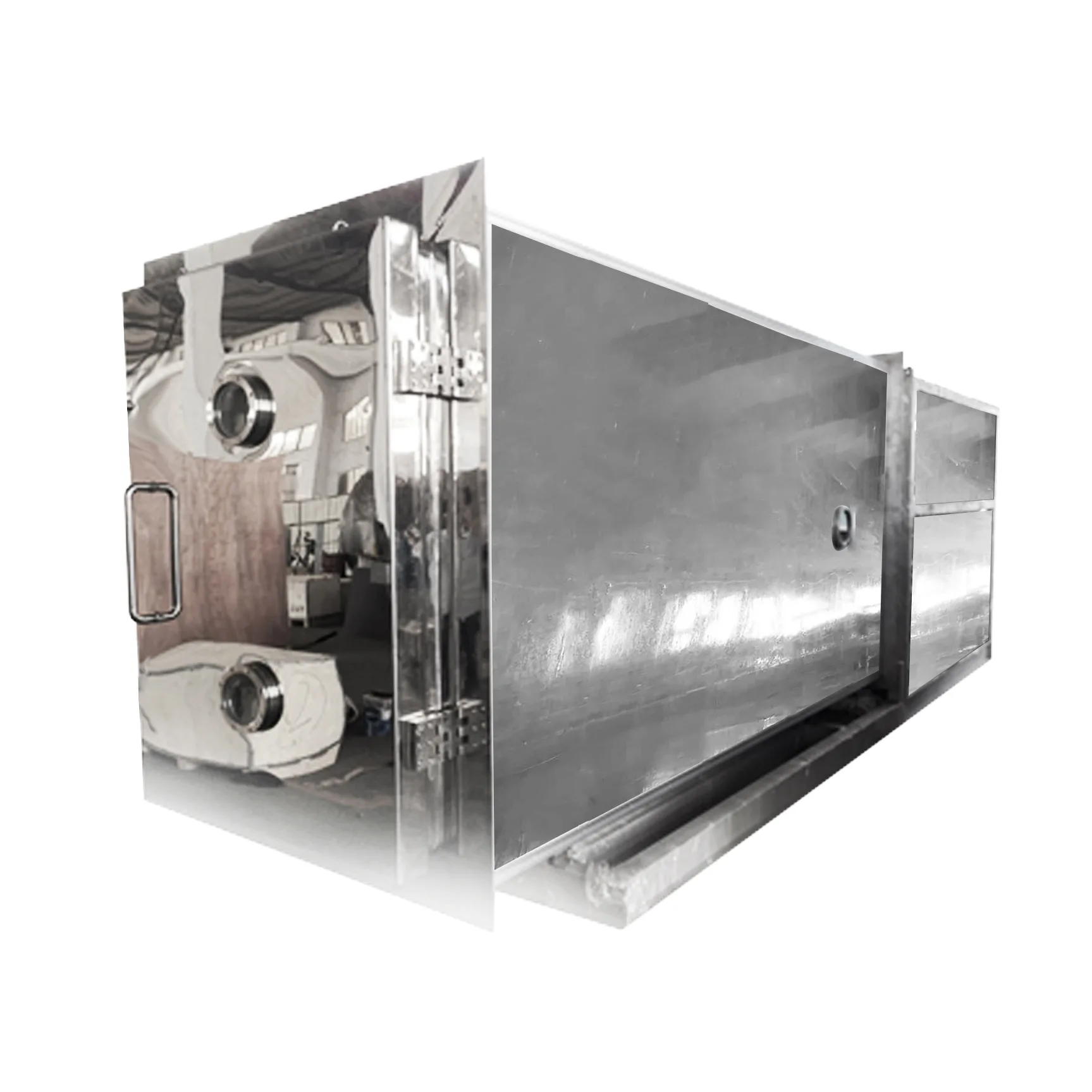

Industrial large freeze dryer

Model | FD-5 | FD-10 | FD-20 | FD-30 | FD-50 | FD-100 | FD-200 | |

|---|---|---|---|---|---|---|---|---|

Dimension(mm) | 3600*1800*2300 | 4800*1800*2300 | 5300*1800*3000 | 6500*2100*3000 | Diameter 2400 Length 7000 | Diameter 2400 Length 11000 | Diameter 2400 | |

Drying area(㎡) | 5 | 10 | 20 | 30 | 50 | 100 | 200 | |

| 50kg | 100kg | 200kg | 300kg | 500kg | 1000kg | 2000kg | |

Water catch capacity | 5kg | 15kg | 30kg | 450kg | 750kg | 1500kg | 3000kg | |

Function | Freezing and Drying in one Chamber or Freezing and Drying separated | Freezing and Drying separated | Freezing and Drying separated | |||||

Chamber material | SUS304 or SUS316L | SUS304 | ||||||

Shelf material | SUS304 or Aluminium alloy | Aluminium alloy | ||||||

Condenser material | SUS304 or Aluminium alloy | |||||||

Freezing Temperature | -35℃ ~ -60℃ or customize | |||||||

Condenser Temperature | -45℃ ~ -70℃ or customize | -40℃ ~ -60℃ or customize | ||||||

Vacuum degree | ≥1pa or customize | ≥5pa or customize | ||||||

Control system | PLC one key automatic control, remote monitoring operation | |||||||

Heating method | Silicone oil is heated by electricity | Pure water is heated by steam | ||||||

| 16kw | 23kw | 46kw | 69kw | 90kw | 162kw | 285kw | |

Weight(kg) | 4000 | 6000 | 8000 | 9500 | 11000 | 15000 | 23000 | |

Other function | automatic cleaning function, sterilization function, block valve function, gland function, etc | Cell | Cell | Cell | ||||

Any area could be customized according to requirements | ||||||||