Working Order

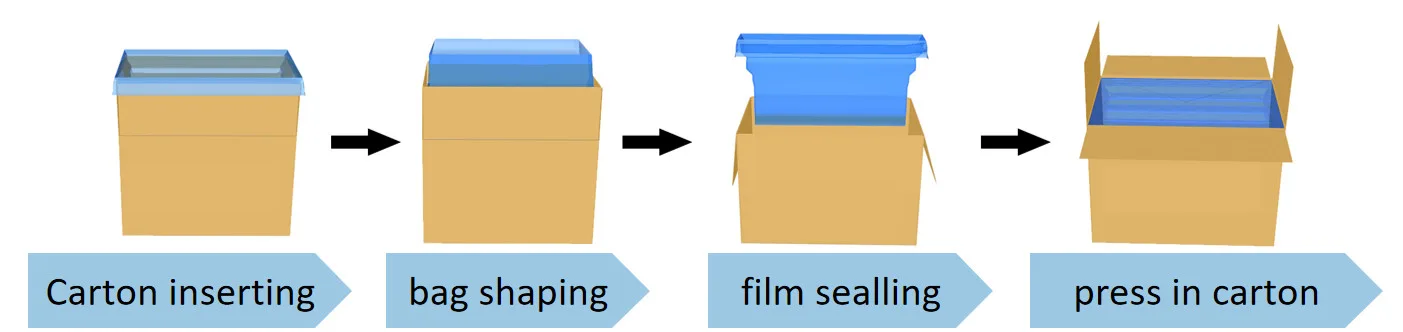

Automatic bag inserter, the machine adopts multi-servo control, automatically completes carton input, positioning, roll film output, box entry, film cutting, folding, and carton output. Automatic bagging is formed synchronously at one time without stopping. It can be connected to the front section automatic carton opener, the rear section automatic carton packer, automatic bag lifting and sealing machine and automatic carton sealing machine to realize unmanned automatic packaging. This bagging machine is suitable for PE film material, and is used for inner bagging of chemical, solid, semi-solid or liquid; food, solid oil, grease, edible oil, condiment, biscuit and other products.

Folding speed | 6-12pcs/min |

Carton Size | L300-600*W200-500*H200-500mm |

Power Supply | 380V 50Hz 3Phaze |

Power | 6KW |

air pressure | 0.6-0.8Mpa |

Air Compressing | 4-7kg/cm³ |

Table Height | 600mm-650mm |

Dimension | L2200mm,W1800mm,H2350mm |

Weight | 1.5 tons |

Safe and beautiful: The machine body adopts a metal door panel + organic glass combination protective door, which has a beautiful texture and safe operation;

Easy to operate: multiple groups of servo control, more accurate and stable operation

Can be used in conjunction with: It can be operated alone, or it can be used in conjunction with automatic packaging lines such as carton openers, carton sealers, bag sealing machines, etc.

Firm and strong: The bag adopts double sealing lines, which is more solid and strong, and the bagging is tight, flat and beautiful;

Humanized design: Automatically complete carton input, positioning, roll film output, box entry, film cutting, folding, and carton output. Automatic bagging is formed synchronously at one time without stopping;

Easy to adjust: It is suitable for packaging of the same carton size at the same time. If the carton specifications need to be changed, the manual adjustment time is about 10-15 minutes

Quality assurance and good stability: Standardized mass production scale, customizable. The performance of the machine parts is precise and durable, with multiple groups of servo control, no vibration during the operation, stable operation, long life, and high efficiency.