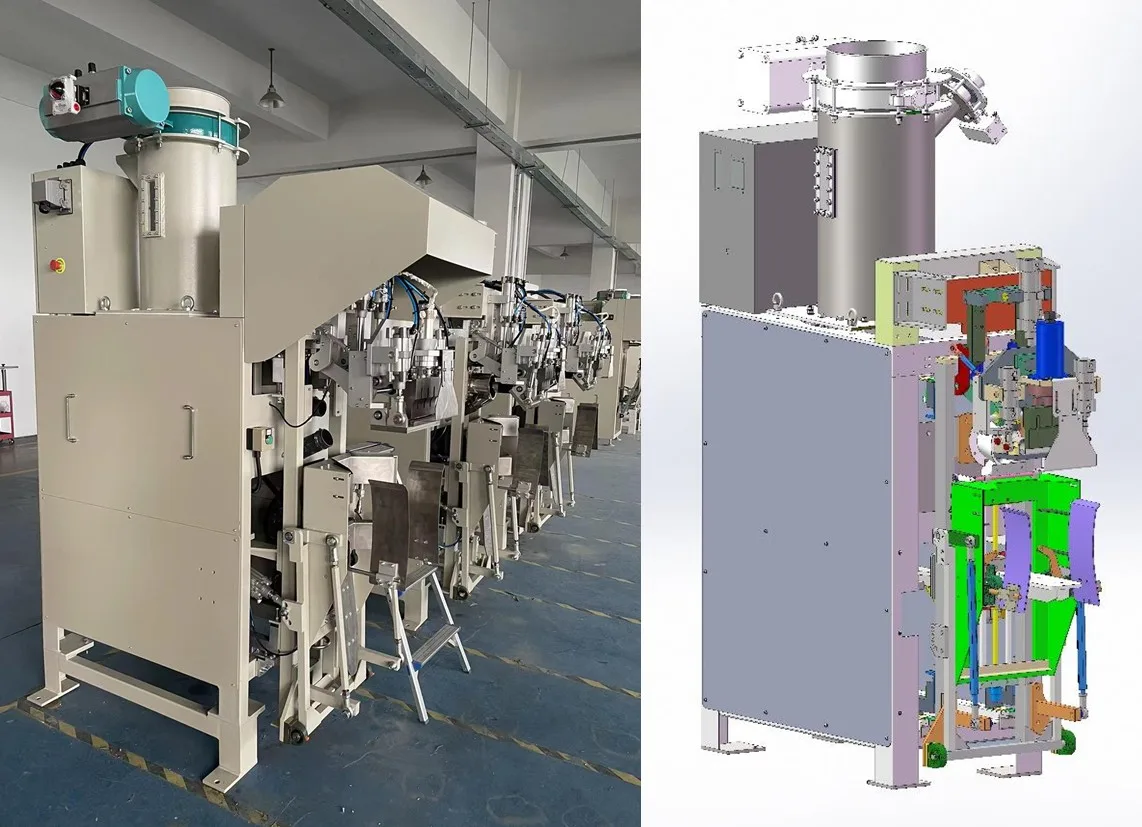

밸브백 포장기

기술적 특징

- 1Adopt air flotation feeding system, suitable for valve bag filling; real-time weighing (gross weight type).

- 2Equipped with compressed air access device.

- 3Dust collector pipe interface.

- 4Soft connection installed between the feeding port of the packing machine and the intermediate hopper.

Each filling unit includes the following parts:

- 1Pressure regulating valve, pneumatic ball valve and manual ball valve.

- 2Inflation control according to the filling speed.

- 3Fast and slow feeding control valve.

- 4Used to cut off the material flow, including a rubber hose; controlled by the cylinder to control the coarse feeding and fine feeding

- 5Air cushion.

- 6Connected with the filling nozzle to reduce the wear of the inner surface of the filling nozzle, which is conducive to filling.

- 7Filling nozzle

- 8Equipped with a bag pressing mechanism, it can automatically check the bag insertion situation.

- 9Dust collection hood.

- 10Arranged above the filling nozzle.

- 11Bag return mechanism with bag push function

- 12The entire bag push mechanism is driven by a cylinder, and the pushed bag will fall vertically onto the belt conveyor in front of the equipment. The frame of the entire bag push mechanism is connected to the packaging machine body through a leaf spring group, and is connected to the weighing sensor at the top. The bag push mechanism includes a bag holding side plate, which can stabilize the bag that has left the filling nozzle so that it can be fixed in the working position of the sealing device. The height of the bag holding saddle is manually adjusted by the operator.

- 13Each bag filling unit includes the following electrical components/functions

- 14Weighing sensor with a rated load of 200kg

Ultrasonic sealing device

- 1A lift-able ultrasonic welding device, placed on the top of the filling nozzle.

- 2A general frequency converter, installed in the control cabinet.

- 3A dust suction device at the bag valve port