作業指示書

自動袋詰め機は、マルチサーボ制御を採用し、カートン投入、位置決め、ロールフィルム排出、箱入れ、フィルム切断、折り畳み、カートン排出までを自動で行います。自動袋詰めは、停止することなく、同期して一度に行われます。前段自動カートンオープナー、後段自動カートンパッカー、自動袋上げ・シール機、自動カートンシール機と接続することで、無人自動包装を実現します。この袋詰め機はPEフィルム素材に適しており、化学薬品、固体、半固体、液体、食品、固形油、グリース、食用油、調味料、ビスケットなどの内袋詰めに使用されます。

折りたたみ速度 | 6~12個/分 |

カートンサイズ | 長さ300~600mm*幅200~500mm*高さ200~500mm |

電源 | 380V 50Hz 3相 |

力 | 6kW |

気圧 | 0.6~0.8MPa |

Air Compressing | 4-7kg/cm³ |

Table Height | 600mm-650mm |

Dimension | L2200mm,W1800mm,H2350mm |

重さ | 1.5 tons |

Safe and beautiful: The machine body adopts a metal door panel + organic glass combination protective door, which has a beautiful texture and safe operation;

Easy to operate: multiple groups of servo control, more accurate and stable operation

Can be used in conjunction with: It can be operated alone, or it can be used in conjunction with automatic packaging lines such as carton openers, carton sealers, bag sealing machines, etc.

Firm and strong: The bag adopts double sealing lines, which is more solid and strong, and the bagging is tight, flat and beautiful;

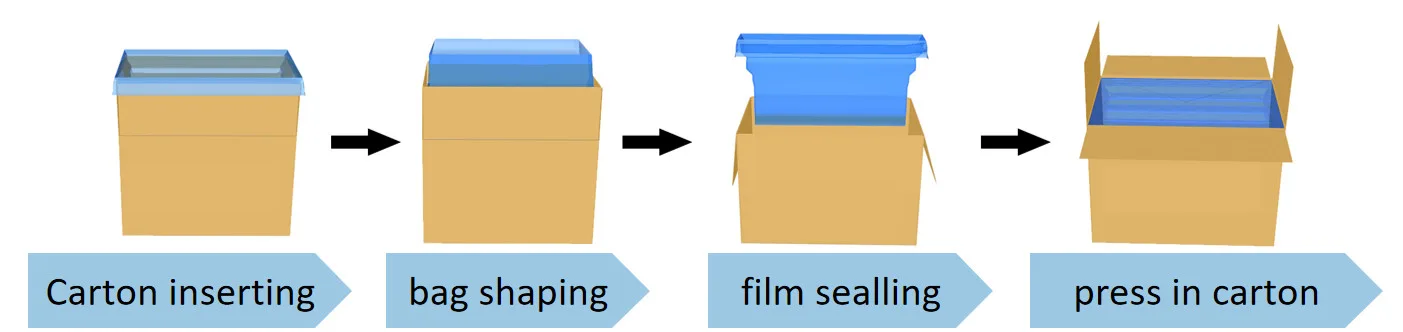

Humanized design: Automatically complete carton input, positioning, roll film output, box entry, film cutting, folding, and carton output. Automatic bagging is formed synchronously at one time without stopping;

Easy to adjust: It is suitable for packaging of the same carton size at the same time. If the carton specifications need to be changed, the manual adjustment time is about 10-15 minutes

Quality assurance and good stability: Standardized mass production scale, customizable. The performance of the machine parts is precise and durable, with multiple groups of servo control, no vibration during the operation, stable operation, long life, and high efficiency.